Burner Services

Trusted Industrial Burner Startup, Commissioning, & Combustion

Burner Got You Down?

From Ignition to inspection, we've got your back.

An industrial burner is a basic and primary component in your mechanical system. Your entire business depends on its successful operation. You need a partner you can trust. Our services will keep your production running 24/7.

TIRED OF LOSING MONEY AND WASTING ENERGY?

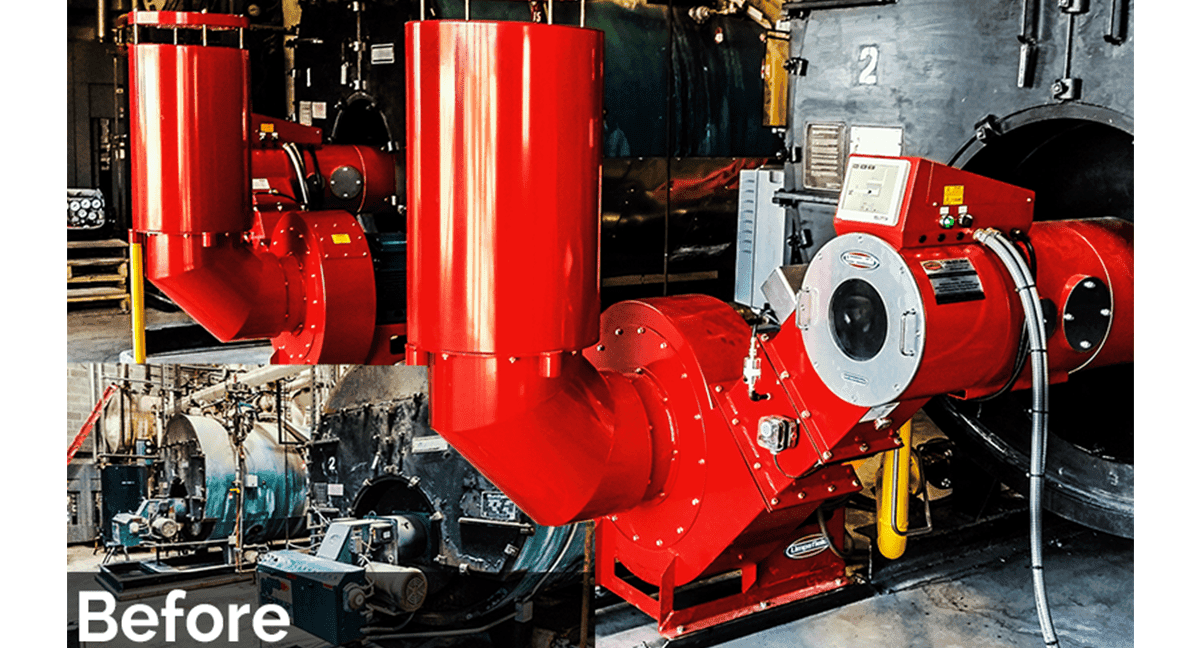

In a production facility one of your main goals is to reduce operating costs. If your company is progressive, you want to lower your carbon footprint. A burner retrofit offers wonderful returns in these areas. Our tailored solutions result in reduced fuel consumption and boiler stack emissions. Our maintenance services improve the production of your facility by decreasing downtime and reducing expensive repairs.

Industrial Burner Services Capabilities

Expert Design, Maintenance, and 24/7 Services for industrial Burners

We provide full-service burner solutions — including design consulting, emissions monitoring, safety device testing, and parts inventory.

INDUSTRIAL BURNER DESIGN

We are here to help you make sense of your burner and its application. Our design services ensure your new burner meets the demand of your production. We work with your team to understand your goals of the project: cost, efficiency, and automation.

BURNER MAINTENANCE

An industrial burner is expensive to install and run. We work with our partners to make sure we provide you with the most diligent maintenance program. We start your program with a Combustion Analysis and Burning Tuning Report. Using these findings, we tune your burner for optimal performance. With routine maintenance, your operation costs are less because of better efficiency and fewer repairs.

24/7 INDUSTRIAL AND COMMERCIAL BURNER SERVICES

Our industrial burner service technicians are factory-trained and are on call 24/7. We can perform our burner diagnostics and make repairs on site. How we help:

Safety device testing

Process industrial burner services

Flame safeguard services

Emissions monitoring

Certified Opacity Testing

Extensive parts inventory

Code compliance

Combustion analysis and adjustments to air-to-fuel ratios

Parallel positioning and ageless controls

O2 Trim

Fully metered, cross-limited combustion controls

Fuel conversions (natural gas, oil, propane, methane, tallow)

BURNER SERVICES SPOTLIGHT: 02 COMBUSTION

The primary goal of burner combustion is to achieve the correct fuel-air ratio. This can be done manually or automatically with the help of O2 Combustion Trim.

The issue with manually tuning your combustion air. Because air is always changing; temperature, humidity, and pressure. Without automation, it is impossible to have an optimal fuel to air ratio. For safety, the burner needs to have excess oxygen to ensure combustion.

Automation to the Rescue. For an optimal air – fuel ratio, we can install an electronic sensor into the boiler stack. This sensor connects to a control panel that measures oxygen and sends a signal to the burner’s air supply control damper. With an O2 Combustion Trim system we can supply the exact amount of O2 to complete combustion. For properly tuned burners, you can achieve a gas savings of 2% – 4% per burner. Typical paybacks are achieved within two years of installation.

Your Partner in Reliable Burner Performance

Maximizing uptime and efficiency through expert service.

When it comes to industrial burner services, you need a trusted partner. We understands the critical role that burners play in your mechanical system and the impact on your business operations. At our company, we specialize in providing comprehensive startup, commissioning, and combustion services for industrial burners. We prioritize your production uptime by ensuring the reliable operation of your burners 24/7. If you’re tired of losing money and wasting energy, our tailored solutions can help you reduce operating costs and lower your carbon footprint. Through burner retrofits, we optimize fuel consumption, minimize boiler stack emissions, and improve overall facility efficiency. With our diligent maintenance services, you can count on decreased downtime and fewer costly repairs. Contact us today for a free estimate and discover how our expertise in industrial burner services can benefit your business.

SCHEDULE YOUR SERVICE TODAY!

GET THE HELP YOU NEED FOR ALL THINGS MECHANICAL

Related Industrial Burner Articles

Burner

Preventative Maintenance

Burner Tuning: Best Practices for Achieving the Perfect Air-to-Fuel Ratio

Fuel-fired heating equipment is something all facilities depend on. So, it’s essential your facility is getting the most out of… Read more »

Burner

8 Valuable Tips For Selecting an Industrial Burner

When it comes to selecting an industrial burner, there are many variables to consider. Of course, you’ll need to identify… Read more »

Boiler

Burner

Burner Flame Sensors and Safeguard Controls

Boiler flame sensors and safeguards are tools to help ensure your burner is working properly. They keep you safe from… Read more »

Boiler

Burner

Burner Retrofits 101 (Real World Examples)

A burner is a key component in ensuring the overall efficiency of your boiler system. As burners age, moving parts… Read more »