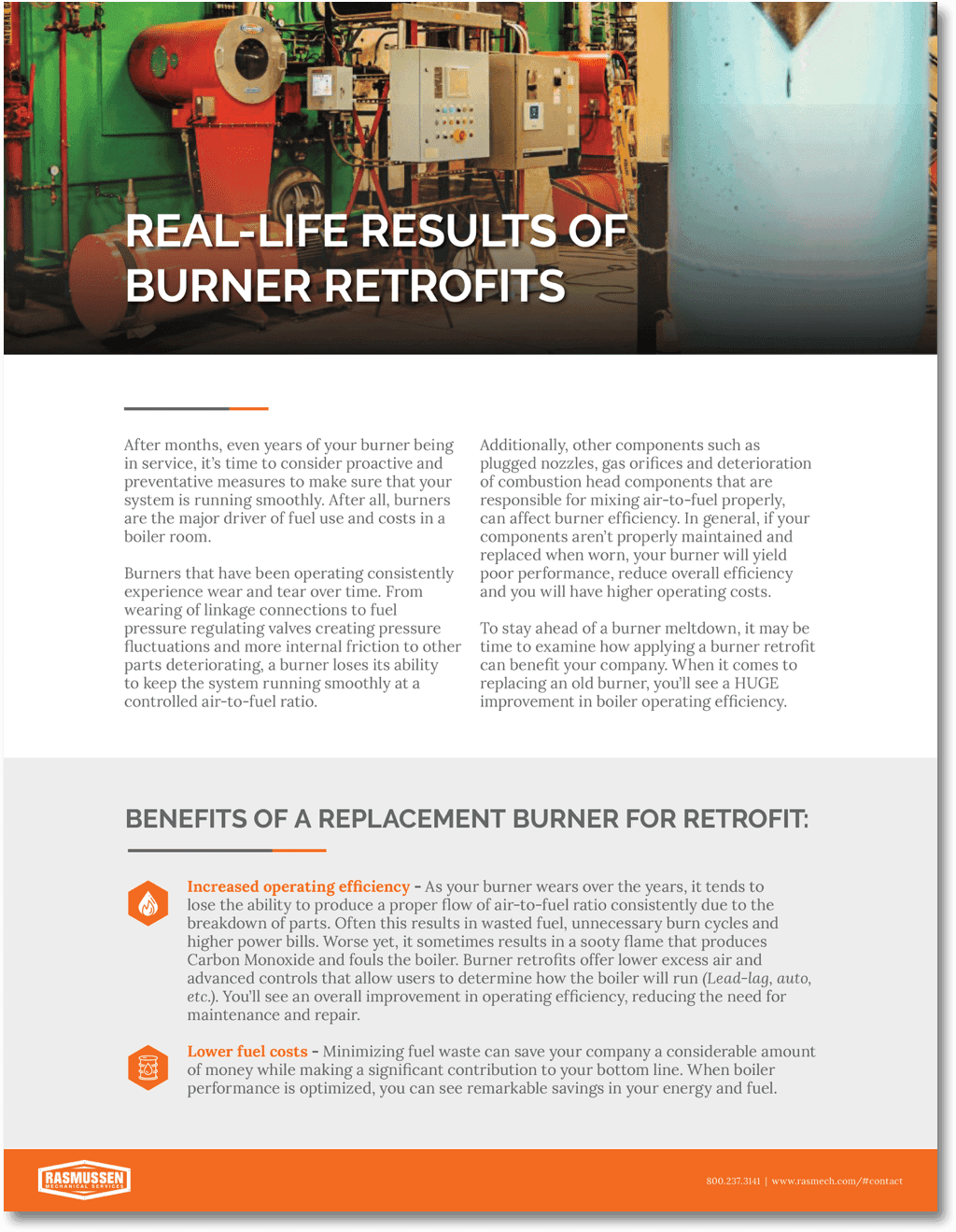

real life results of burner retrofits

real life results of burner retrofits

Discover how applying a burner retrofit can benefit your system!

Burners that have been operating consistently experience wear and tear over time. From wearing of linkage connections to fuel pressure regulating valves creating pressure fluctuations and more internal friction to other parts deteriorating, a burner loses its ability to keep the system running smoothly at a controlled air-to-fuel ratio. In general, if your components aren’t properly maintained and replaced when worn, your burner will yield poor performance, reduce overall efficiency and you will have higher operating costs. To stay ahead of a burner meltdown, you need to examine how applying a burner retrofit can benefit your system. When it comes to replacing an old burner, you’ll see a HUGE improvement in boiler operating efficiency.

What's inside?

How retrofits increase operating efficiency

How retrofits lower fuel costs

How retrofits increase safety

How retrofits prove to be a worthy investment

Download Brochure

Other Resources

You’ll find these helpful!

Boiler

Superheated Boilers: A Complete Guide to High-Efficiency Steam Systems

If you work in a facility where steam plays a critical role in operations—power generation, chemical processing, or manufacturing—you’ve likely… Read more »

HVAC

Commercial HVAC Replacement Guide: Signs, Costs, & ROI

Considering a commercial HVAC replacement? This guide covers when to replace your system, what it will cost, and the benefits… Read more »

Boiler

Steam Trap Survey Secrets: What Top Plants Do Differently

A steam trap survey is an audit of all steam traps in a facility to determine their operating condition and… Read more »

HVAC

HVAC Temperature Controls that Everyone Should Know

The Importance of Knowledgeable Operators in HVAC Temperature Controls No matter how advanced HVAC temperature controls are, their success hinges… Read more »