Boiler Repairs

Schuyler, Nebraska

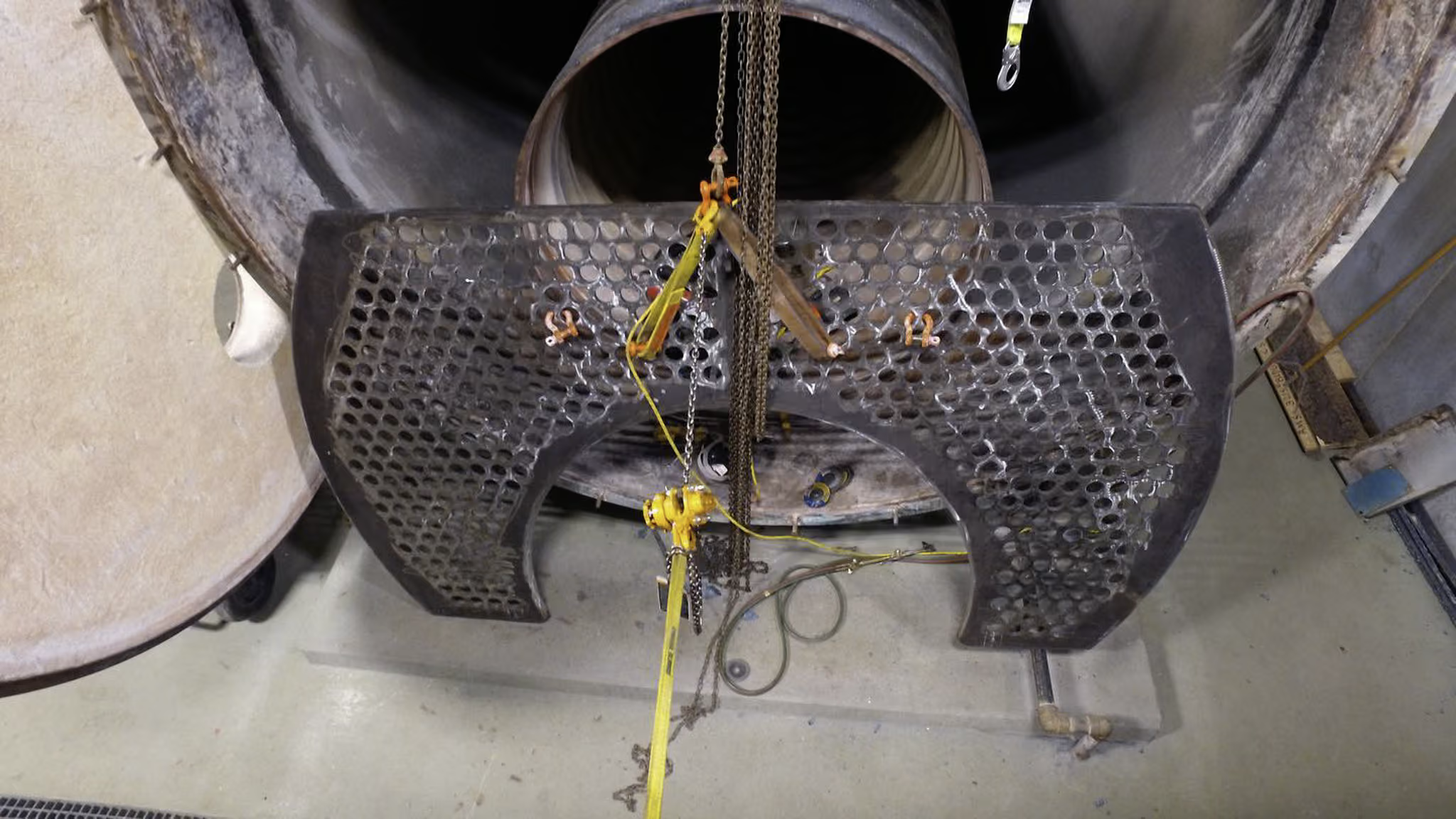

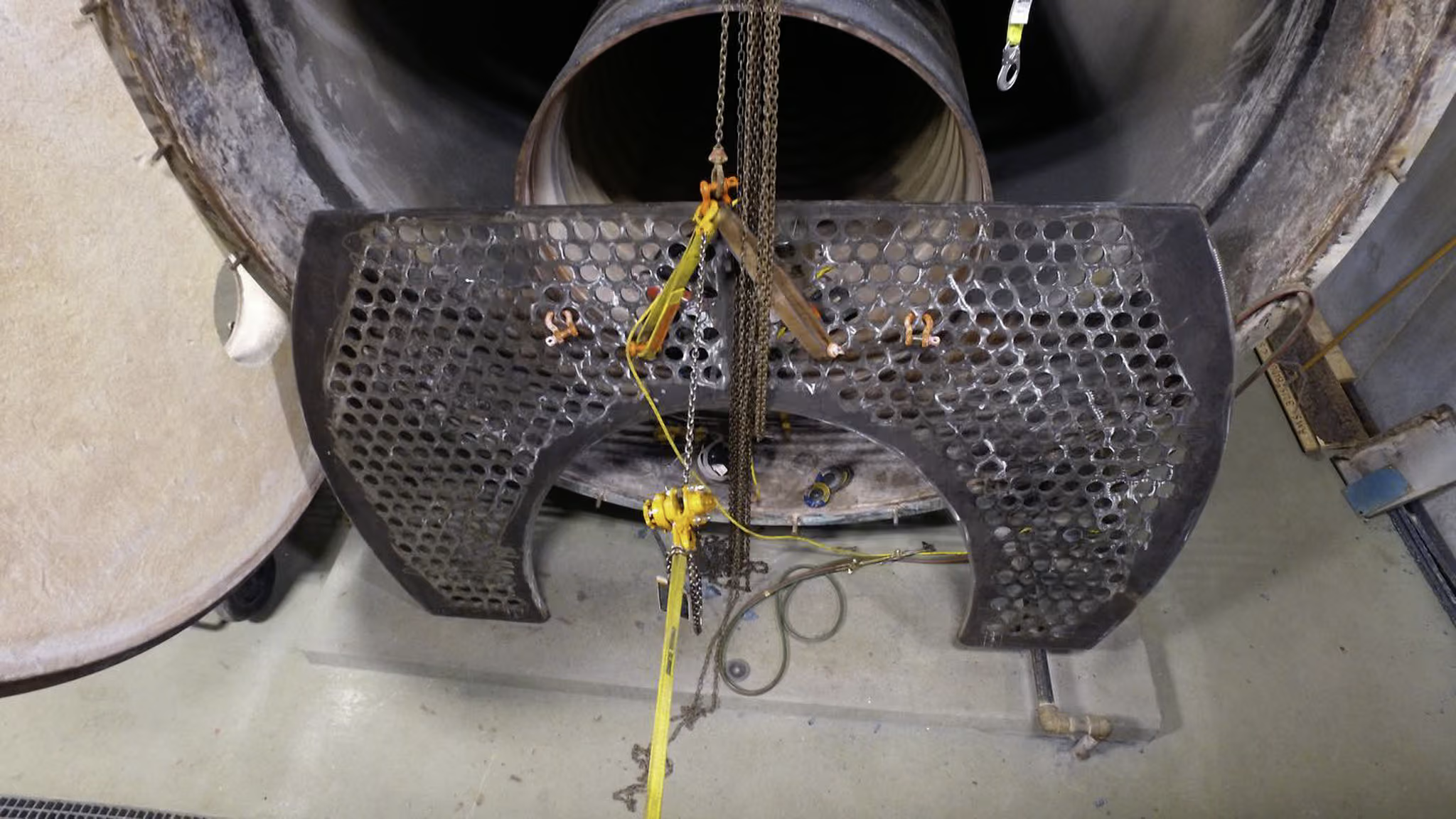

For Cargill's boiler repairs, Rasmussen Mechanical Services removed all of the existing tubes and rear tube sheet from the boiler. The burner and refractory were also removed. For an increase in efficiency, rifled (XID) tubes were installed mechanically and sealed by welds. A new burner cone and block refractory were installed. Upon completion of the boiler repairs, the unit was boiled out and the burner was tuned for efficiency and proper operation.

Successfully removed and replaced 484 2.5" OD boiler tubes.

Performed a rear tube sheet repair that was 3/4" thick and 130" in diameter.

Tube sheet welds passed ultrasonic weld tests by a third party inspection company.

Boiler repaires meet all NBIC, ASME and State Boiler Requirements.

About US

Rasmussen Mechanical Services is a full-service mechanical contractor with over 55 years of experience supporting commercial and industrial facilities. Our teams work across a wide range of mechanical systems, providing the knowledge and field experience needed to complete projects of varying size and complexity.

Each project we take on is approached with careful planning, clear communication, and a focus on quality execution. Our crews are experienced working in active facilities, coordinating with other trades, and adapting to site-specific conditions to keep work moving efficiently and safely.

From initial coordination through project completion, Rasmussen Mechanical Services remains focused on delivering dependable results that support long-term system performance. This project reflects our ongoing commitment to practical solutions, skilled workmanship, and consistent execution across every job we perform.

- Boiler Repair

- Burner Services

SCHEDULE YOUR SERVICE TODAY!

GET THE HELP YOU NEED FOR ALL THINGS MECHANICAL