Commercial And Industrial Burner Services

Trusted Industrial Burner Startup, Commissioning, & Combustion

THE BURNER EXPERTS FOR 50+ Years

For decades, RMS has been providing burner services for many variations of heating and process equipment within the industrial, institutional, and commercial markets.

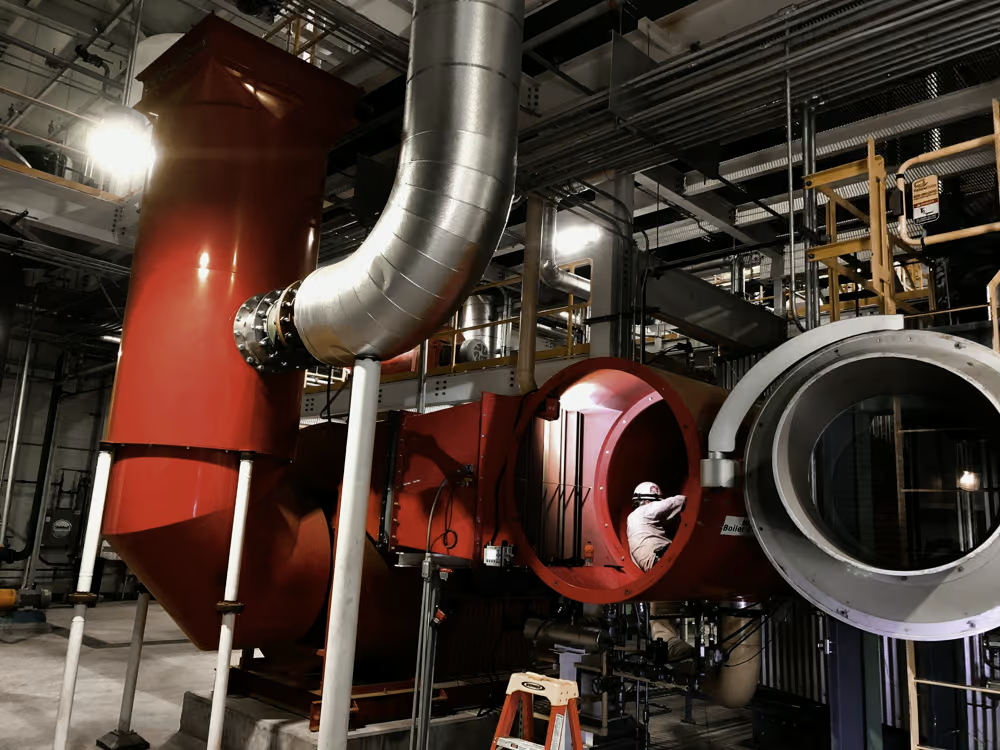

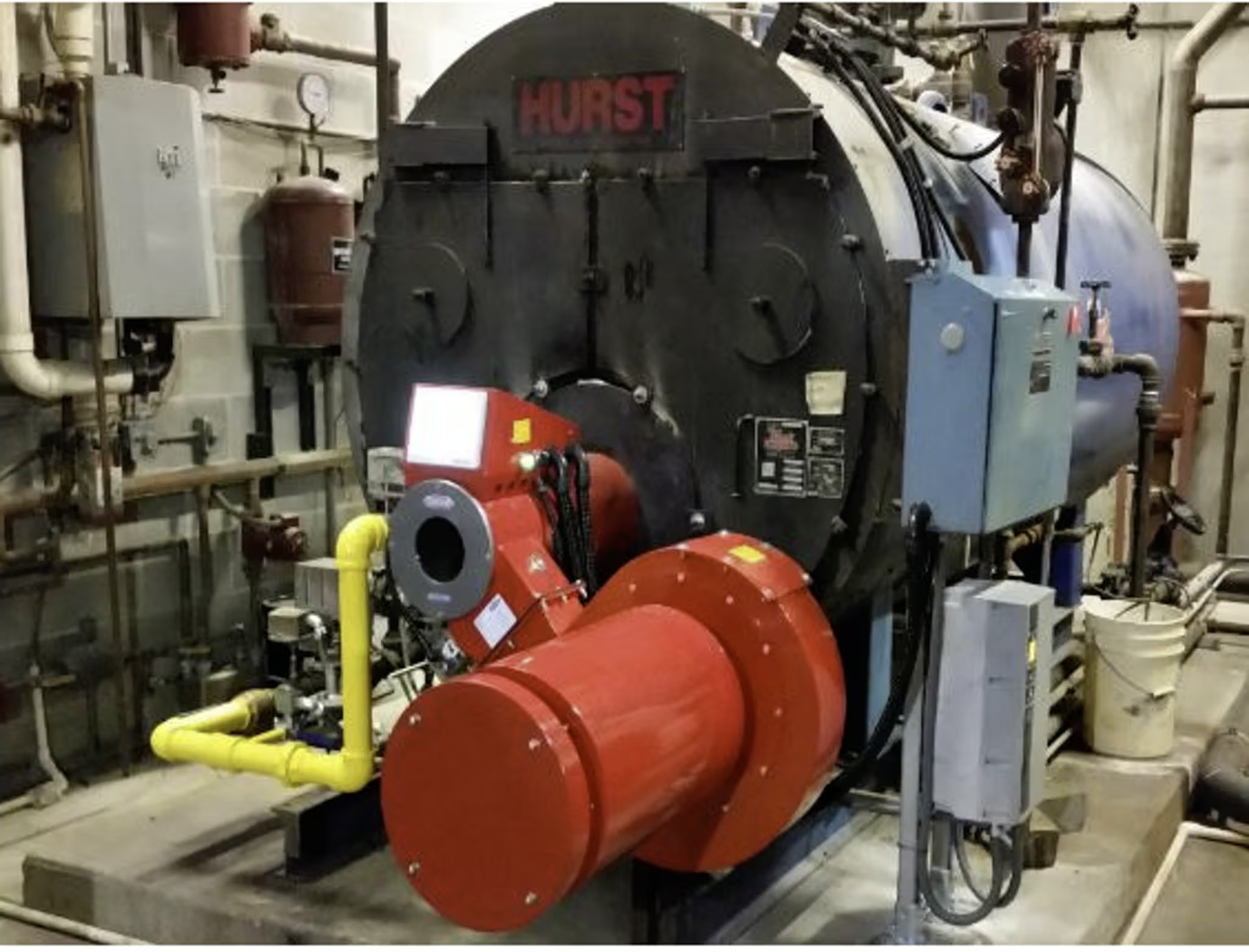

Burner System and/or Burner Controls Retrofits, Conversions, Upgrades, or New Installations

Process Burner Services

Combustion Analysis & Adjustment to Air-to-Fuel Ratios

Flame Safeguard Services

Parallel Positioning and Linkageless Controls

O2 Trim

Fully Metered, Cross Limited Combustion Controls

Fuel Conversions (Natural Gas, Oil, Propane, Methane, Tallow)

Emissions Monitoring

Extensive Parts Inventory

BURNER MAINTENANCE AGREEMENTS

Scheduled preventative maintenance services provided by RMS will minimize unexpected equipment failure which often leads to unplanned facility or process downtime. In addition, RMS can assist in capturing several of the following desired savings advantages:

Increased Production

Reduced Fuel and/or Electricity Costs

Reduced Emissions

Improved Boiler and Boiler Room Safety

Increased Life of Equipment

Code Compliant

SCHEDULE YOUR SERVICE TODAY!

GET THE HELP YOU NEED FOR ALL THINGS MECHANICAL

More Than Just Burner Repair

From burner parts, to boiler rentals, to new installation and everything in between. We have the knowledge and know how to ensure the job gets done right the first time. We commonly perform service, repair or installation on brands like: Cleaver Brooks, Autoflame, Limpsfield, Superior Boiler, Power Flame, Weil McClain And Many More!

Call Us At 1-800-237-3141 To See How We Can Help

Burner Retrofit 101 (Real World Examples)

As your burner wears over the years, it tends to lose the ability to produce proper flow of air-to-fuel ratio consistently. This is generally due to the wear and tear on old parts. Often this results in wasted fuel, unnecessary burn cycles and higher power bills.

Back To The Basics: Boiler Burners

When pulling outside air in to feed a burner, you must consider the temperature of that air. When there are large swings in the temperature of the supply air for the burner, it can cause combustion problems. We commonly start seeing combustion issued after a 15 to 20 degrees temperature change.

Burner Flame Sensors And Safeguards

Careful aiming of the infrared scanner, directed at the pilot and main flame, is imperative. This is because hot refractory in a boiler or oven can reflect these infrared rays as well. If improperly aimed this can lead to the flame safeguard falsely indicating a flame is present. This type of sensor works well even in smoky environments.