Membrane air dryers are an essential when compressed air needs to be dried before use. These dryers use membrane technology to remove moisture from compressed air, ensuring that the air is free from moisture. In this article, we will discuss everything you need to know about these dryers.

What Are Membrane Air Dryers?

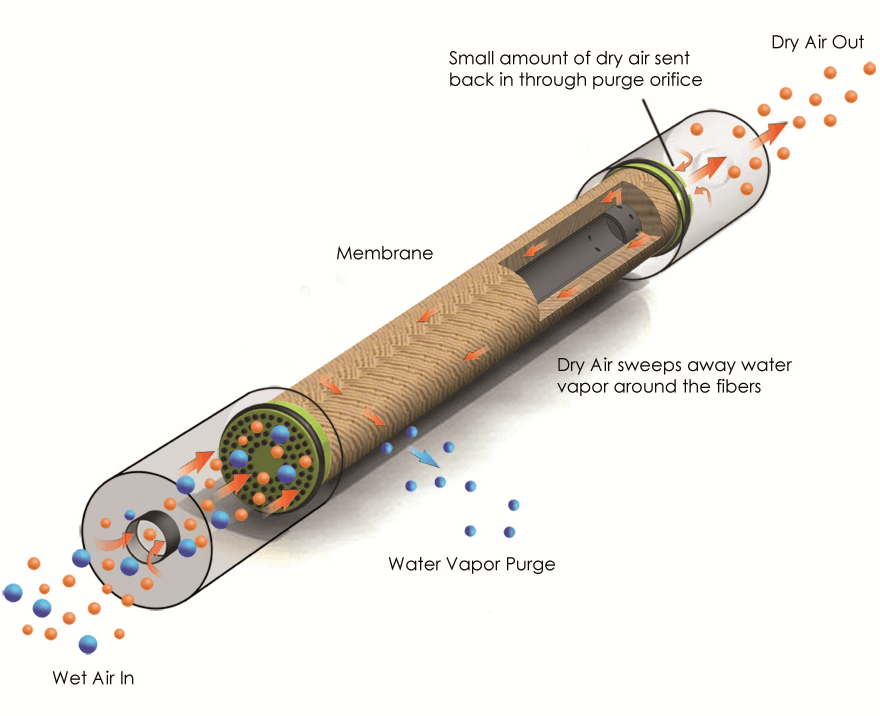

Diagram From Ultra-Filter

These air dryers use a membrane to remove moisture from compressed air. The membrane is made of a polymer material that is permeable to water vapor but impermeable to air. When compressed air passes through the membrane, the water vapor in the air separates from the air, resulting in dry compressed air.

2 Types Of Dryers

There are two main types of these air dryers: hollow fiber membrane dryers and flat sheet membrane dryers.

Hollow fiber membrane dryers: In these dryers, compressed air passes through a bundle of hollow fibers. The water vapor in the air permeates through the membrane of the fibers and is removed by a purge air stream.

Flat sheet membrane dryers: In these dryers, compressed air passes through a flat sheet membrane. The water vapor in the air permeates through the membrane and is removed by a purge air stream.

Advantages

Energy efficient: These dryers do not require electricity or refrigeration to operate, making them more energy efficient than other types of air dryers.

Low maintenance: These dryers have no moving parts, making them easy to maintain and repair.

Easy to install: They are compact and easy to install, requiring minimal space.

Quiet performance: These air dryers don’t have any moving parts, so they operate quietly.

Disadvantages

Clean Air Required: These systems operate efficiently as long as there is no oil or other particulates in the air.

Limited capacity: Membrane air dryers have limited capacity and may not be suitable for high flow applications.

Conclusion

Air dryers are an essential component in a variety of industrial applications. They use membrane technology to remove moisture from compressed air, ensuring that the air is free from moisture and other contaminants. They are energy efficient, low maintenance and easy to install. While they have some limitations in terms of capacity and dew point range, they are suitable for a wide range of industrial applications.