If you’re running a commercial or industrial boiler system, you’ve probably heard the term lead-lag boiler controls. This guide explains why lead-lag controls are critical, how they work, and what you need to know to get the most out of them.

What Are Lead-Lag Boiler Controls?

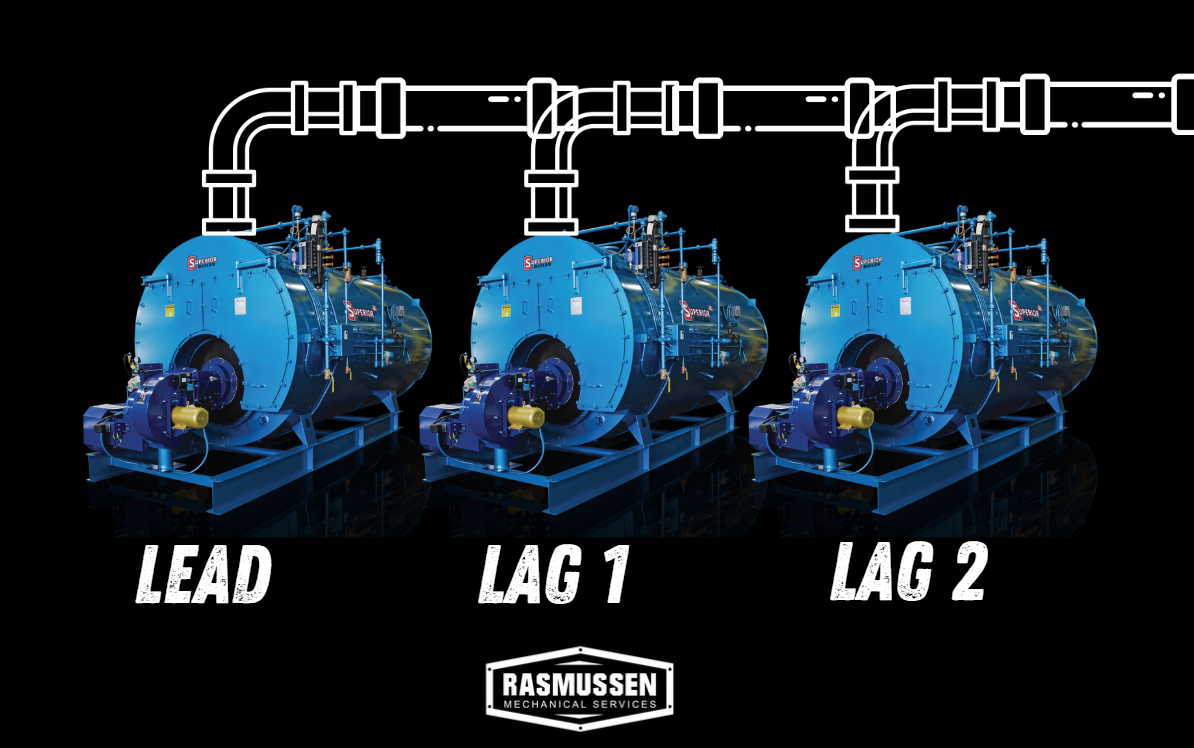

Lead-lag boiler controls are systems that manage the sequencing and modulation of multiple boilers in a facility. Instead of running all boilers simultaneously, a lead-lag control system prioritizes efficiency by operating only the boilers required to meet current demand.

Lead Boiler: This boiler starts first and handles the base load.

Lag Boiler(s): These boilers come online incrementally as demand increases.

When demand decreases, the lag boilers shut down in reverse order, and the lead boiler remains active until no longer needed.

Key Features of Lead-Lag Boiler Control Systems

Sequencing Logic

Boilers are programmed to start and stop based on system demand, usually determined by header pressure or temperature.

The sequence ensures that boilers come online in a logical order, avoiding unnecessary cycling.

Automatic Rotation

The lead boiler rotates periodically to ensure even wear across all units. Rotation schedules can be time-based (e.g., daily or weekly) or runtime-based.

Modulating Control

Instead of operating boilers at full on/off cycles, many systems modulate the firing rates of boilers to match demand more precisely, boosting efficiency.

Fail-Safe Features

If the lead boiler fails, the system automatically promotes a lag boiler to lead status, ensuring uninterrupted operation.

Technical Insights: How Lead-Lag Controls Work

Lead-lag controls rely on accurate data collection and sophisticated decision-making algorithms. Sensors in the system monitor parameters such as steam pressure, water temperature, and flow rates. The control system analyzes this data to determine when to start, stop, or modulate boilers.

Lead-lag controls rely on accurate data collection and sophisticated decision-making algorithms. Sensors in the system monitor parameters such as steam pressure, water temperature, and flow rates. The control system analyzes this data to determine when to start, stop, or modulate boilers.

When demand exceeds the capacity of the lead boiler, lag boilers activate sequentially. As demand decreases, lag boilers shut down in reverse order, leaving the lead boiler to manage the base load. In systems with modulating burners, firing rates adjust dynamically to match energy output precisely to demand, eliminating waste.

Implementation Considerations

When setting up a lead-lag control system, it’s crucial to:

Ensure Proper Sensor Placement: Sensors should be installed in locations that accurately reflect system conditions. This is typically in the common header piping rather than on individual boilers.

Configure Control Setpoints Appropriately: Setpoints for starting and stopping boilers should be calibrated to match the system’s load characteristics and desired performance outcomes.

Regular Maintenance and Testing: Routine checks and maintenance of the control system and associated components are essential to ensure reliable operation.

Benefits of Lead-Lag Controls for Modular Boiler Systems

The Pacific Northwest National Laboratory (PNNL) highlights that modular systems combined with lead-lag controls offer unmatched flexibility and efficiency. With smaller boilers that operate in tandem, these systems allow precise load matching.

The Pacific Northwest National Laboratory (PNNL) highlights that modular systems combined with lead-lag controls offer unmatched flexibility and efficiency. With smaller boilers that operate in tandem, these systems allow precise load matching.

Advantages Include:

Reduced Idle Losses: Small boilers can be turned off completely, eliminating standby losses.

Rapid Response Times: Modular systems respond quickly to demand changes.

Scalability: Modular designs accommodate future growth by adding more boilers.

Conclusion

Lead-lag boiler controls are a must-have for any multi-boiler system. By optimizing sequencing, modulating output, and scaling operations based on real-time demand, these systems deliver significant cost savings. This improves efficiency, and extends the systems lifespan.

Whether you’re running a modular setup or retrofitting existing equipment, lead-lag controls provide the intelligence needed to stay ahead in today’s energy-conscious world. Invest in a well-designed system and watch your boiler room transform into a model of efficiency.