Condensate tanks are part of a condensate return system, and are used to store all the condensate water returned from a steam system. They are typically located near the boiler and their size is determined by the steam load on a system.

They are an important part of the steam system because it increases the overall efficiency of the boiler. The returned condensate is responsible for preheating the fresh make-up water to compensate for any lost water volume. This reduces the amount of energy needed to transform water into steam and results in lower operating/utility costs.

How Does A Condensate Tank Work?

A condensate tank is the collection tank in which all returning condensate is collected. There are three reasons we want to collect and use condensate returns:

1. They have already gone through the boiler’s chemical treatment process.

2. They typically have temperatures ranging from 130ºF to 220ºF

3. They reduce the amount of cold feedwater (usually 50ºF to 60ºF) that the system needs.

The condensate tank supplements returns with make-up water as needed. Make-up or feedwater is added using a solenoid valve. If water drops below a sensor in the tank, the valve opens allowing more make-up water to be added. Make-up water is cold, so a steam preheater is used along with steam sparging to bring the water up to a higher temperature.

A sparging system is a steel tube with hundreds of holes drilled into it at different angles. It sits inside and runs the length of the condensate tank. Steam is then injected into the water through the pipe that is submerged in the tank. This preheats and helps to remove oxygen and carbon dioxide from the water before it is fed into the boiler or DA. This is not used in all tanks.

Maintenance Of A Condensate Tank

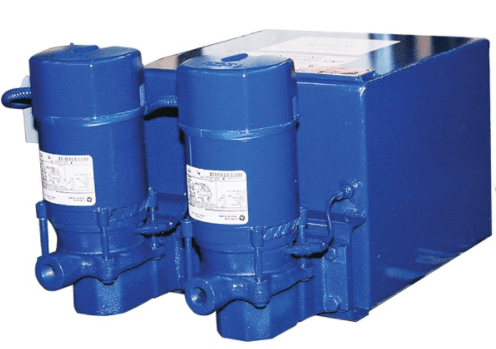

Close up of a condensate tank pumps. All photo rights to shipcopumps.com

Condensate tanks themselves require very little maintenance. You should inspect the internals of the tank annually for signs of corrosion and clean the unit on the same schedule. If there are any visible leaks that appear they should be addressed immediately. In addition, if insulation is showing signs of damage be sure to repair or replace it.

We Can Help

If you need a new condensate tank or are experiencing problems that have you stumped, call the experts. Reach out for a free estimate or give call us at 1-800-237-3141.