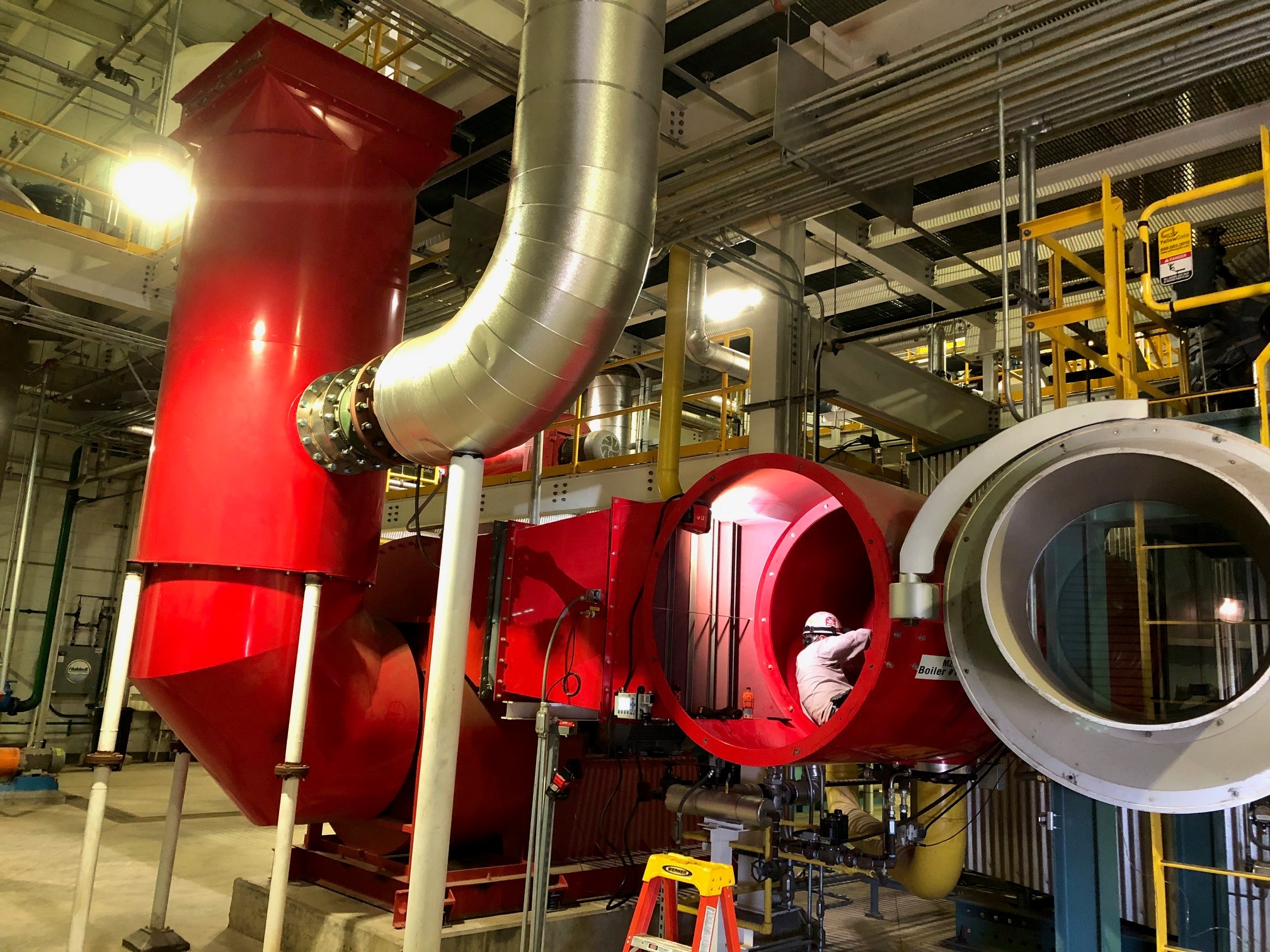

A boiler’s burner is an essential component that is responsible for heating water or producing steam. The efficiency and performance of a boiler depend on proper burner tuning. This article provides a comprehensive guide to tuning your boiler’s burner for optimal performance.

Importance of Burner Tuning

Tuning your boiler’s burner is crucial because it affects the efficiency, performance, and longevity of your boiler. A poorly tuned burner can lead to increased fuel consumption, higher emissions, and reduced lifespan of your boiler. By regularly tuning your burner, you can maintain optimal efficiency, minimize emissions, and extend the life of your boiler.

Steps to Tune Your Burner

IMPORTANT NOTE – Boiler tuning should always be done by a professional company.

1. Inspection: Begin by inspecting the entire system, including the fuel lines, combustion chamber, and exhaust vents. Look for any signs of corrosion, leaks, or blockages, and repair or replace any damaged parts.

2. Air-to-Fuel Ratio: The air-to-fuel ratio is one of the most critical aspects of burner tuning. The ideal air-to-fuel ratio depends on the type of fuel and the design of the burner. An incorrect air-to-fuel ratio can cause inefficient combustion, increased emissions, and higher fuel consumption.

3. Adjusting the Air and Fuel Settings: Adjust the air and fuel settings on the burner control panel until you optimize the air-to-fuel ratio. Complete this by adjusting the air damper, fuel pressure, and combustion air flow.

4. Testing: It is important to test the burner to ensure it is functioning correctly. This can be done using a flue gas analyzer to measure the carbon monoxide (CO) levels and determine the efficiency of the burner.

Regular Maintenance

Tuning your burner is not a one-time event. Regular maintenance and tuning are necessary to ensure optimal performance and efficiency. Perform a burner tune-up at least once a year, or more frequently for older boilers.

Burner Safety Considerations

Proper Ventilation: Adequate ventilation is critical for ensuring safe operation of a burner. A lack of ventilation can lead to a buildup of toxic gases, such as carbon monoxide, which can be fatal.

Combustion Safety: the burner’s control system should be equipped with safety features such as low oxygen cut-off, high temperature limit control, and overpressure protection. You should also have bubble testing performed on the gas train at regular intervals.

Operator Training: All operators of a burner should be trained in safe operation and maintenance procedures. This includes understanding how to safely handle fuels, how to respond to emergency situations, and how to perform routine maintenance tasks.

Burner Tuning Summary

Take a look at this video for a deeper dive into burner tuning and how it optimizes performance! Burner tuning is a crucial aspect of ensuring safe and efficient operation of industrial processes, boilers, and furnaces. By adjusting the parameters such as fuel and air flow rate, ignition, and combustion stability, you can optimize your burner. Regular burner tuning can help to reduce emissions and maintain safe and stable combustion conditions. It is important to seek the expertise of experienced technicians for proper and efficient burner tuning.

Call the experts for all your burner needs. Here is how we help:

Safety device testing

Flame safeguard services

Emissions monitoring

Certified Opacity Testing

Combustion analysis and adjustments to air-to-fuel ratios

Parallel positioning and ageless controls

Fully metered, cross-limited combustion controls

Fuel conversions (natural gas, oil, propane, methane, tallow)