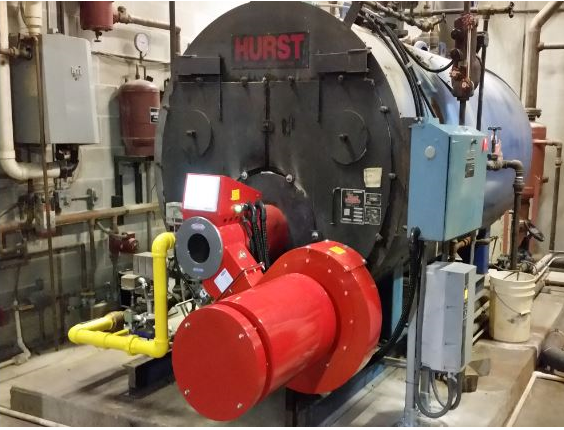

The controls on a boiler system are essential for maintaining efficiency and proper combustion control. Just like everything in the digital world, boiler controls have come a long way in the past decade. They can now also be used to control a number of other boiler processes. Today we are going to discuss everything you need to know about your boilers controls.

Boiler Control Basics

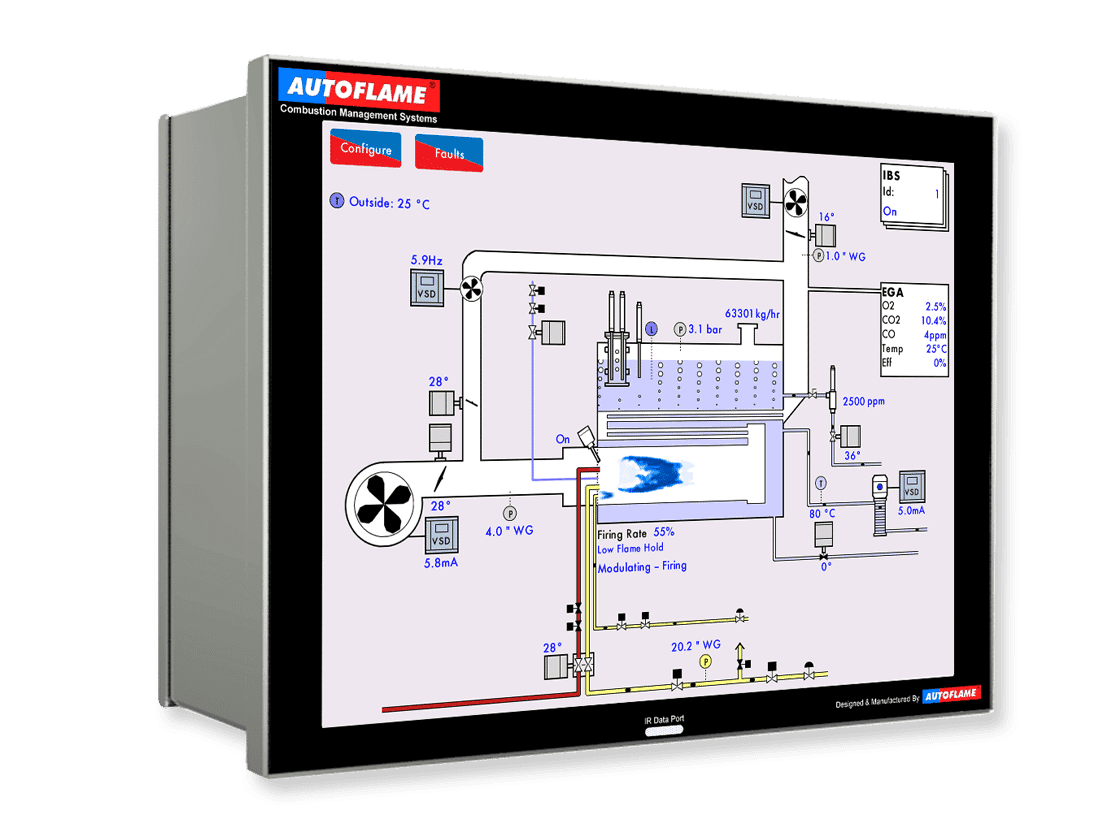

Modern controls are effectively small computers that monitor and control different components on your system. This allows you to have real time feedback on boiler and burner performance. It also allows facility managers to manage all boiler processes from a single screen in some cases. This can even allow for remote monitoring of the boiler.

Flame Safeguard

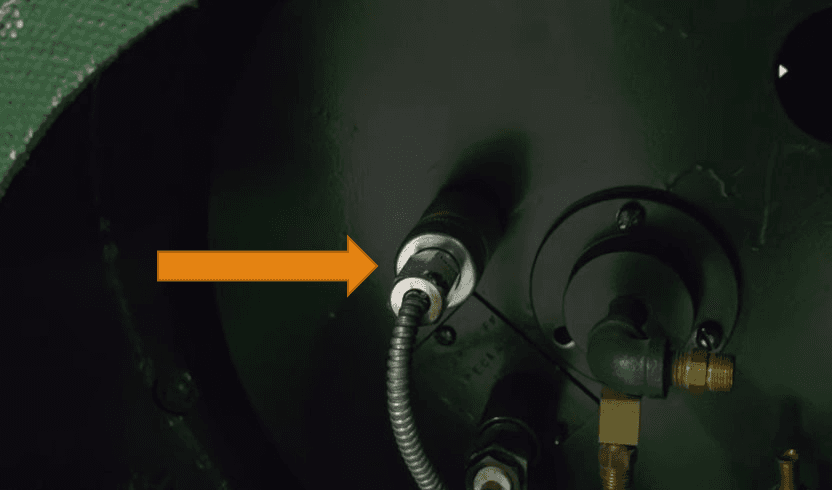

Ultra Violet Scanner

One of the primary functions of boiler controls is to ensure the burner is operating as it should. This means using fame sensors to ensure the flame ignites the fuel is being supplied to the burner. If for some reason the flame doesn’t ignite correctly these systems will indicate a pilot failure and cycle the burner off. There are 3 types of flame sensing controls:

1. Rectification (flame rod, photocell)

2. Infrared

3. Ultraviolet

Gas Control Valves With Servo Motors

Gas Control Valve

Controlling the amount of fuel that is going into the burner is another feature that is run using controls. This allows the controls to close off fuel supply when flame sensors indicate an issue with the flame. It also allows the controls to shut off fuel for any other boiler related issue. A low water condition for example.

Air Dampers With Servo Motors

Another common sight in modern boiler rooms is air dampers that can be adjusted using boiler controls. This helps to ensure a proper air to fuel ratio is being met and that the burner is operating efficiently.

O2 Sensors

O2 Sensors

The oxygen to fuel ratio effects boiler efficiency. Too much oxygen and your system will run inefficiently. Too little oxygen and you have incomplete combustion resulting soot buildup and harmful emissions. O2 sensors used to find the balance between too much and too little oxygen. They are placed in the boiler stack and analyze the exhaust from the burner and the amount of oxygen present. This information is then relayed back to the controller which can increase or decrease the amount of air being brought in to optimize combustion.

Water Level Controls

Maintaining proper water level is essential for industrial or commercial boiler operation. A combination of water level probes, automated Top Blowdown and Bottom Blowdown can be implemented. This allows the controls’ system to react when a low water situation occurs.

Boiler Controls Equipment

There is no shortage of equipment that can be hooked up to boiler controls and in this article we only skimmed the surface. Oil pressure sensors, steam pressure controls, outside temperature controls, oil control valves, capacitance probes, TDS probes and water control valves, just to name a few.

Autolame’s Mk8 MM

Our favorite system is the Autoflame Mk8 MM because it allows for complete control over the burner as well as entire boiler system. Product details:

Manage virtually all boiler processes from a single 12.1” multi-touch screen interface without any added modules.

Ideal for steam and water boilers (watertube or firetube), kilns and steam generators. Designed for oil, natural gas or both fuels.

Linkageless servomotor system and automated flame safeguard create conditions for unmanned boilerhouse.

Modbus connectivity allows for remote monitoring and management.

Control more with software unlocks. Access codes unlock advanced features without the inconvenience of hardware changes or added modules:

Autoflame water level management

Analogue water level (requires Autoflame water level)

TDS/Top blowdown

Bottom blowdown

Draught control

Direct Modbus connectivity

First out annunciation

Fully metered, cross-limited control

Steam flow & water flow metering

Contact us at [1-800-237-3141](tel: 1-800-237-3141) for all your boiler needs!